PRODUCTS GUIDE REPAR2

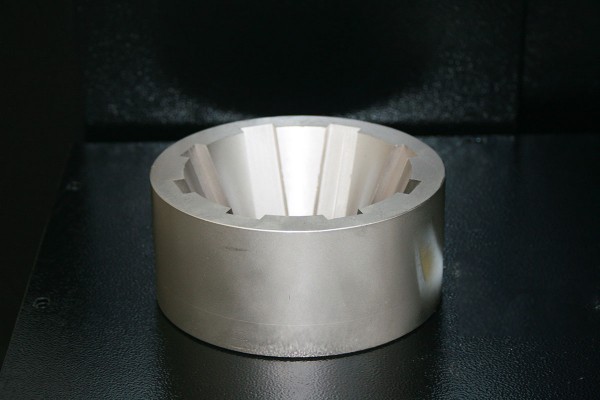

The slotting machine is similar to a verticle shaper. The ram carrying the slotting tool reciprocates in a verticle guide-way of the machine. The Slotting Machine can manufacture flat and contour surfaces, slots. And internal grooves. Note: At the bottom of my article you will find the PDF downloadable link. May 08, 2012 Know about the slotting machines including types of slotting machine, applications of slotting machine, different models of slotting machines and other machine tools applications from slotting.

Nowadays Repar2 is the leader in the field of safety on machines for mechanical industry exporting most of its production in Europe and worldwide

Slotting Machine Pdf

Increased attention and care for safety in working places has enabled Repar2 to make a proper engineering of the product with the result of offering a range of top quality machine guards.

The main target for Repar2 is the constant improvement of its products, offering a wide standard range, customised solutions, easy fitting, full comfort and safety for the operator

A Slotting machine may also be known as heavy-duty shaper. Slotting machine resembles a shaping machine in all respect except that the ram instead of reciprocating to and fro in the horizontal plane, moves up and down in the vertical plane. Therefore, the slotting machine is sometimes called as vertical shaper. In this article we will see slotter machine functions and types of slotting machine .

See also: Major Shaping Machine parts and its Functions

Functions of Slotting Machine

The main function of a slotting machine is to remove metal from a piece of a work to bring it to the required shape and size. This is accomplished by holding the work rigidly on the machine and a reciprocating single point tool mounted on tool head. The single point tool moves along a vertical axis over the work piece. The pinion which is in mesh with the main gear gets its drive from a pulley through a belt by motor. The gear is coupled to the slotted disc. The circular motion of slotted disc is converted into the reciprocating one with the help of connecting rod. The crank pin can be formally set in the slot of slotted disc at different distances from the centre for verifying the length of the ram stroke. The position of the stroke is adjusted with the help of hand lever provided for the stroke adjustment. Slotting machine is usually provided with horizontal circular worktable, but coordinate tables are also provided some times. The table is mounted directly over a bed casting and heavy work may be placed on it. The circular table can be revolved by hand or power fed. It is graduated around its outer edges and work can thus be mounted and turned to a predetermined position, depending upon the function for which slotter is designed.

Types of Slotter Machine

Slotting machines are mostly of the following four types:

1. Precision Tool Room Slotter

2. Puncher Slotter

3. General Production Slotter

4. Keyseater Slotter

1. Precision Tool Room Slotter

Tool room slotter is precision type with is use for very precise machining. It is lighter machine and is operate at high speeds. By use special jigs machine can handle a number of equal works on a production basis.

2. Puncher Slotter

Puncher slotter is weighty machine and operational with powerful motor. It is propose to remove large quantity of metal as of large castings or forgings. Length of the stroke is too large.

Slotting Machine Tools

3. General Production Slotter

Production slotter is general type of slotter use for general production work. Drive of ram is by means of slotted disc with connecting rod. Fly wheel is fixed to prevent shock at the end of stroke.

4. Keyseater Slotter

Keyseaters, also identified as keyseating machines with keyway cutters, are specific machines designed to cut keyways. It is similar to vertical shapers; the dissimilarity is that cutting tool on a keyseater enters the work piece as of bottom and cuts on down-stroke, as the tool on a shaper enter the work piece as of the top and cuts downward. One more difference is a keyseater has a guiding system over the work piece to reduce deflection, which results in a closer tolerance cut. Process starts by clamping the work piece to the table by a fixture or vise.

This machine can cut other straight sided features other than keyways. They can also make blind slots, which are slots that do not enlarge through the whole work piece.